The industrial cleaning technology Cryonomic® arrives in Italy with Ikaros srl

Ikaros Srl has been appointed official distributor in Italy, Greece, Cyprus and Malta by the Belgium company ARTIMPEX N.V that produces under the brand name Cryonomic® dry ice cleaning equipments for over 27 years.

The cleaning technique CRYONOMIC® was developed in Belgium, the company is composed by an international team and a worldwide sales, distribution and service network. Today CRYONOMIC® introduces its machines for dry ice blasting in Italy with the company based in Rimini: Ikaros Srl.

CRYONOMIC® is renowned for in-house development and supplying customers with quality performance equipment. The particular technology of its machinery is found in the use of dry ice, a term already known for its importance and fundamental role in the transport and storage of vaccines.

IKAROS SRL:

Ikaros Srl is a company that operates its business activity in Italy and abroad for 25 years in the Oil&gas sector. Ikaros supplies products and services for the use of technical and food gases, collaborating for a long time with the largest producers active in the European market. In this way, Ikaros has developed a technical know-how, especially in storing gas, including carbon dioxide CO2, a fundamental experience for conveying information and awareness about the advantages of dry ice blasting. These are the drivers on which CRYONOMIC® and IKAROS are based to create synergy and solutions for businesses in multiple sectors.

>>The potential of carbon dioxide in cleaning processes

Cleaning with solid CO2, defined as cryogenic cleaning, arises from the convergence of environmental concerns, economic competitiveness and technology, causing industries and governments to re-evaluate each stage of manufacturing processes. In this sense, there are already many companies that have switched from traditional cleaning methods to alternative techniques in response to the need to find cleaning methods more advantageous in terms of time, cost and effectiveness.

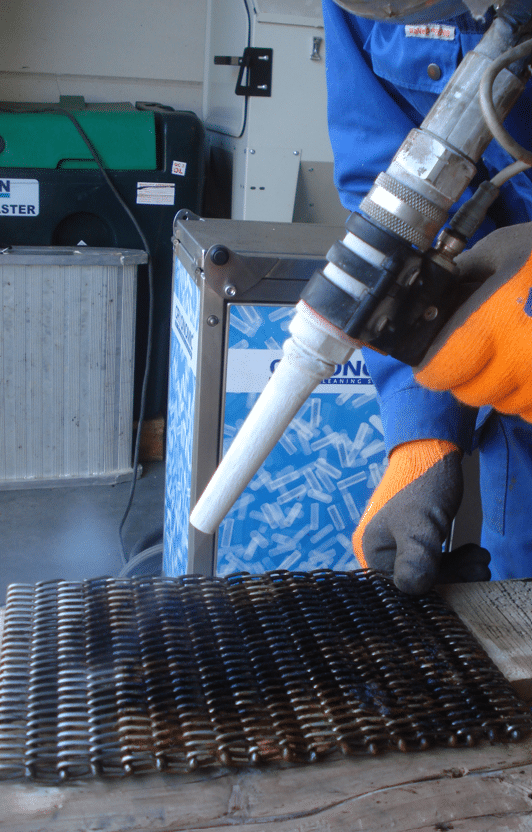

How does it work? – It is a quick, economical and environmentally friendly cleaning process. It occurs by thermal shock, effectively removing dirt without damaging the surface. This method of cleaning is confirmed as ‘unique’ allowing to intervene on multiple surfaces and working environments without generating waste, since pellets, or solid carbon dioxide granules, are 100% dispersed after use.

In what areas does it apply? – Dry ice blasting machines are used in a wide range of applications and sectors, from industrial and maintenance to service and industrial cleaning companies and in all those contexts where classic sandblasting or water cannot be applied.

What are its advantages?

– Speed: it is not necessary to stop the production unit or to disassembly of the equipments, therefore the dead times are reduced.

– Delicacy: dry ice makes it possible to work on delicate surfaces where sandblasting is not suitable, such as glass or wood surfaces.

– Environmentally friendly: by working in the absence of water and sand, waste water and excess solid waste are eliminated, with considerable savings in time and disposal costs.

– Versatility: it is possible to remove different types of dirt, in different environments and types of surfaces.

– Sanitation: carbon dioxide has a bacteriostatic and fungistatic function. In addition, CO2 is effective for disinfection of surfaces as it suffocates parasites and germs.