FOOD GRADE CARBON DIOXIDE: a brief explanation

Carbon dioxide or CO2 is a highly versatile gas that is applied in different sectors such as food and technical – industrial.

Some common uses of carbon dioxide are:

- Carbonation of water or other beverages: from large-scale production to domestic gasifiers;

- Tapping of beer and other draft drinks found in the ho.re.ca sector;

- Removal of air that is in the food packaging (protective atmosphere);

- Extinguishing fire, as for e.g. in CO2 extinguishers or fixed fire extinguishing systems;

- Production of dry ice (pellets and solid CO2 blocks) for food, industrial, pharmaceutical and other uses.

Given the different uses of carbon dioxide it is possible to find on the market both “industrial” and “food grade” CO2 gas supplies, as well as the most specialized ones.

The distinction between food CO2 and industrial CO2 is not only a label indicating the intended use of the gas, but depends mainly on its degree of purity:

• technical CO2: degree of purity between 95% and 99%;

• pure CO2: between 99% and 99.99%;

• very pure CO2: between 99.99% and 99.99999%.

Let’s see together which are the main difference between food-grade CO2 and industrial CO2…

>> COMPARISON BETWEEN FOOD GRADE CARBON DIOXIDE AND INDUSTRIAL CARBON DIOXIDE:

The main difference between industrial and food CO2 are the controls carried out on the gas which the cylinders are filled, both as purity and as standard required during the bottling phases.

While for industrial gas the level of purity is defined only by the specifications of the manufacturer, for that classified as food CO2 there are well-defined limits on gas purity, and on the maximum permitted percentages of other gases or contaminants.

In particular, the reference legislation is the European Regulation no. EU 231/2012 of 9 March 2012 laying down the specifications for food additives.

This regulation has been taken up and deepened by E.I.G.A. (European Industrial Gases Association) in the document doc. 126/20 “Minimum Specifications for Food Gas Applications.

This results in the obligation of instrumental chemical analysis for each gas lot that is supplied, and the consequent issue of a specific analysis certificate.

The certification confirms that that specific batch of CO2 is suitable for applications in the food sector, and at the same time serves as a protection for the final consumer.

Also for those who use carbon dioxide in aquariums, CO2 being a natural fertilizer, food CO2 is used in aquaria to promote the growth of plants and to regulate the pH of water.

E 290 Food-Grade Carbon Dioxide:

Carbon dioxide or CO2 in food E 290, is considered by European legislation as a food additive, number “E290”. For this reason it is essential that its purity is guaranteed and therefore is qualified for food use. On the other hand, it is also necessary to ensure best practices in handling, transport and storage in order to avoid any possible contamination and to ensure the most complete traceability.

>> THE SOLUTION PROPOSED BY IKAROS:

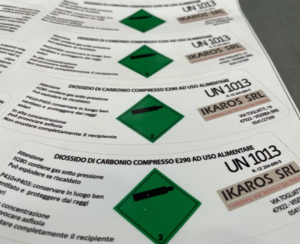

Ikaros is specialized in the supply of co2 gas cylinders E290 certified in order to guarantee the purity of the gas that is inside the cylinder, both to those companies that operate in the food sector and to those who use it in other areas, such as industrial applications.

In addition, the products distribute for food use are certified as being in full compliance with Regulation (EC) Num. 1935/2004 laying down the general principles to be observed for materials intended to come into contact with food (MOCA). We are also authorized by the ASL through the HACCP protocol for the packaging of gases for food use with traceability of production batches for maximum safety (https://www.ikaros.it/quality-certifications/).

One of the solutions to avoid that the CO2 gas is contaminated, is to pay attention to the type of valve used, in fact the residual valve or RPV prevents the entry of foreign substances, thus ensuring the purity of the food gas that is inside.

LEARN MORE ABOUT OUR SERVICES AND FOOD CO2 PRODUCTS:: CLICK HERE!

Do you want to know more?

Contact us and talk with our technicians to find out about benefits available according to your need and application.